Silverton Engineering

Advanced Manufacturing Technology

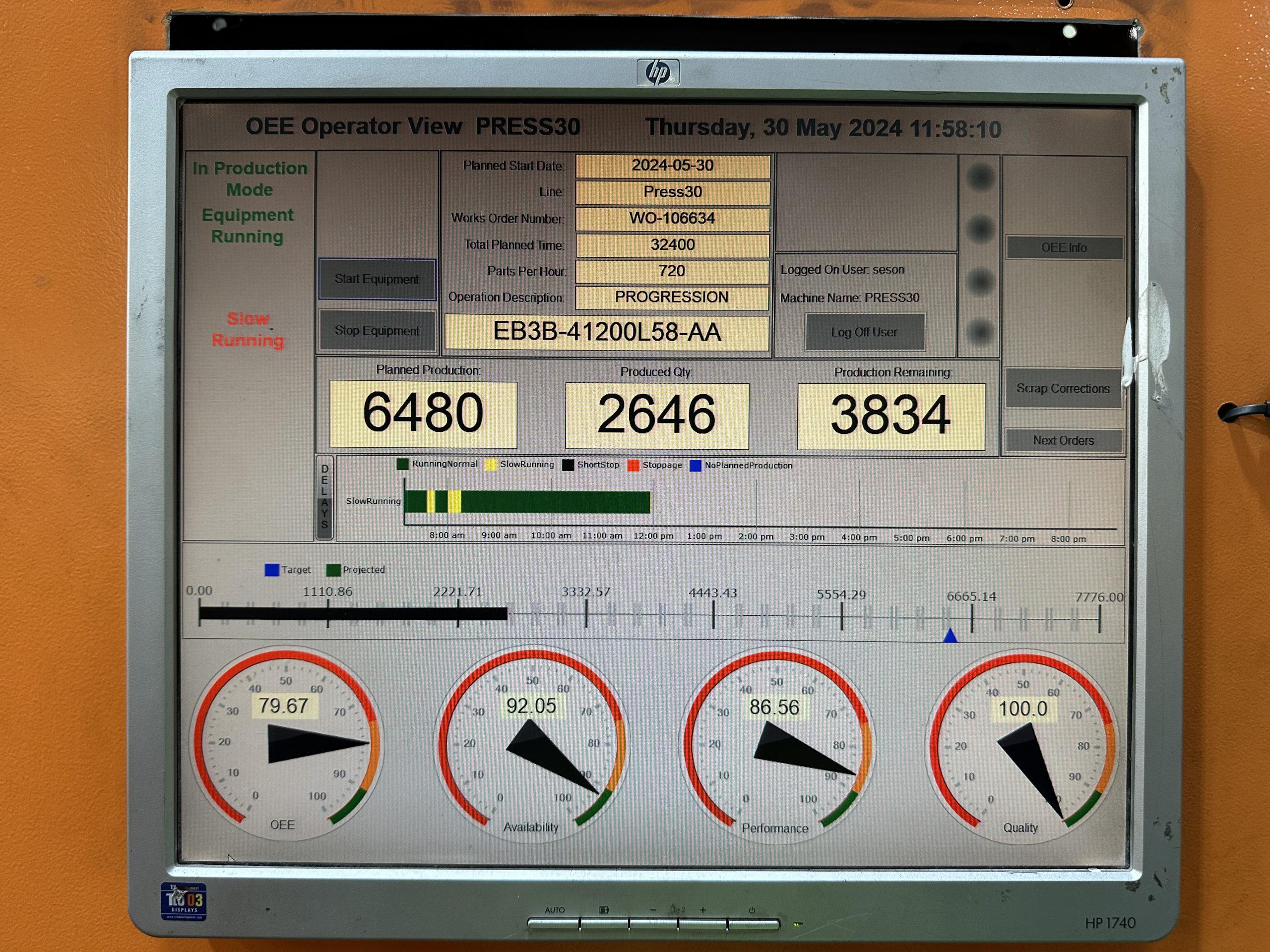

1. Press Plant

Press Plant

Decoiler-Straightener-Feeder / Blanking Line

2. ASSEMBLY PLANT

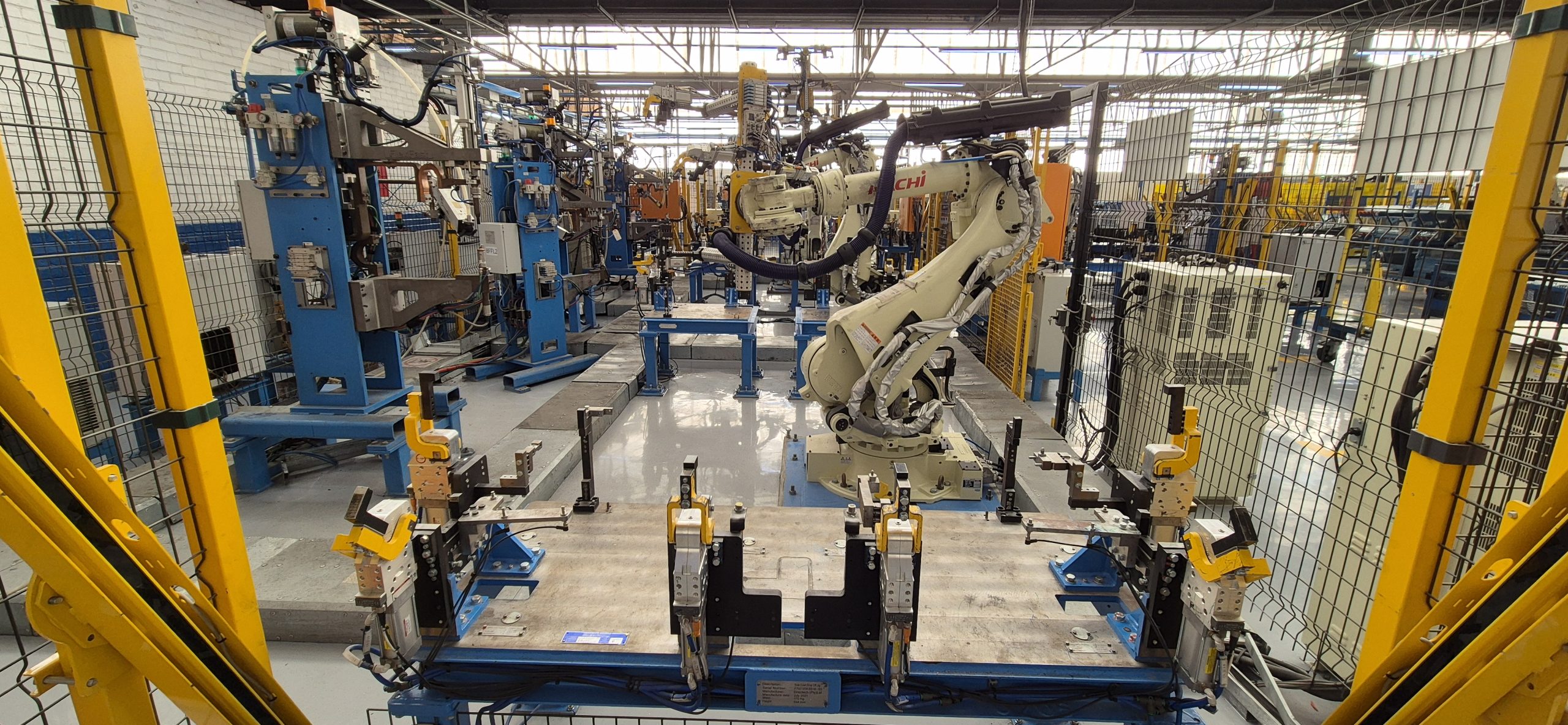

Robotic Welding and Automation

Silverton Engineering utilizes cutting-edge robotic welding technologies to ensure precision, consistency, and efficiency in our manufacturing processes. Our advanced capabilities include resistance spot welding, MIG welding, and drawn arc welding, with robotic arms from renowned brands such as Nachi, Yaskawa Motoman, and Kuka for spot welding, and OTC and Fanuc for MIG welding.

Additionally, we employ Nachi robotic systems for sealer application, ensuring precise and consistent sealing. Gripper and transfer robots, also from Nachi, further enhance our automation capabilities. These robots are seamlessly integrated into fully automated welding cells, designed for maximum productivity.

To maintain superior quality and minimize downtime, our welding jigs are fully error-proofed, preventing defects and ensuring uninterrupted production.

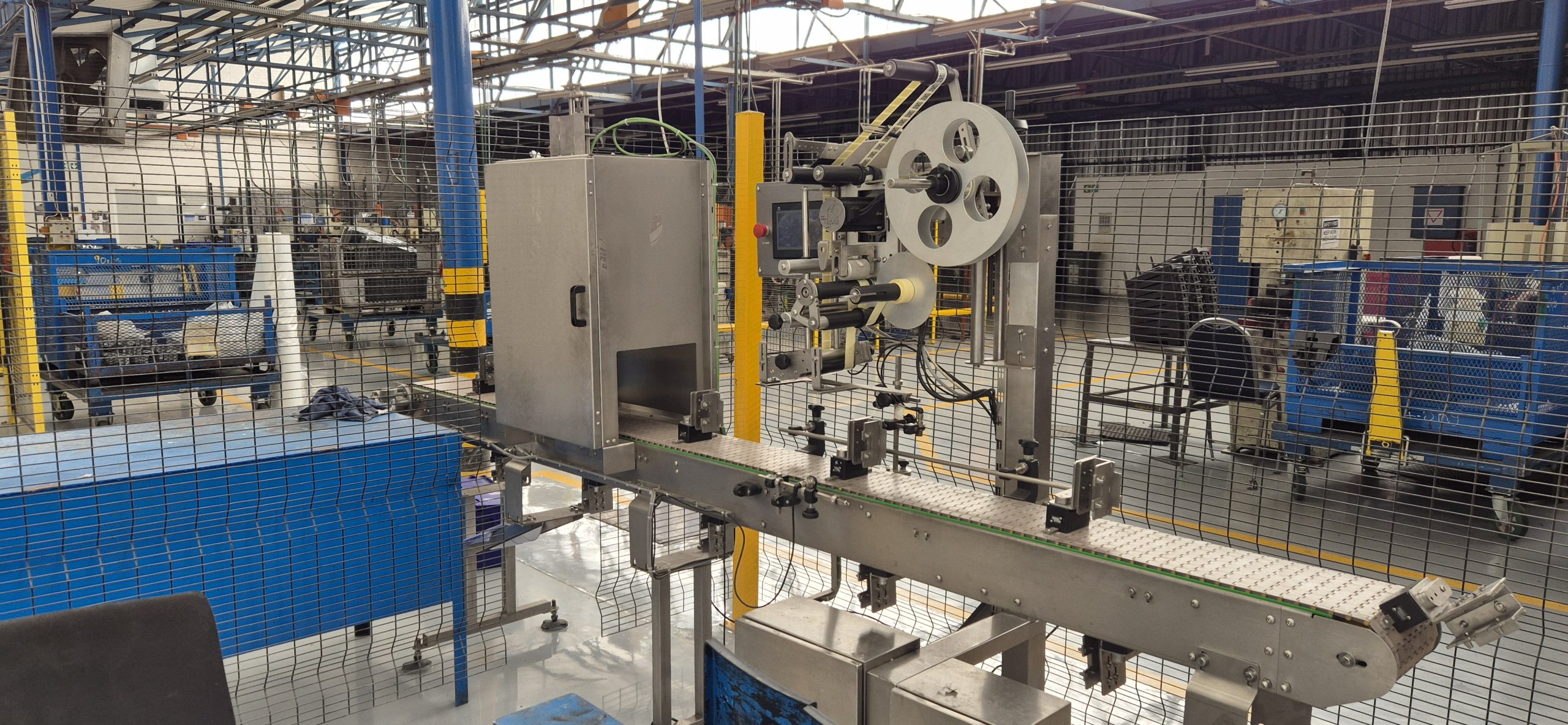

3.Quality Control Technologies

At Silverton Engineering, quality is at the heart of our manufacturing process. We utilize advanced technologies and rigorous methodologies to ensure every component meets the highest standards of precision and reliability in the automotive industry.

Our quality control capabilities include:

Advanced Metrology Tools

– COORD 3 CMM (Coordinate Measuring Machines) for precise dimensional analysis (1 off 1800 x 1300x 1000mm and 1 off 2300 x 1300 x 1500 mm)

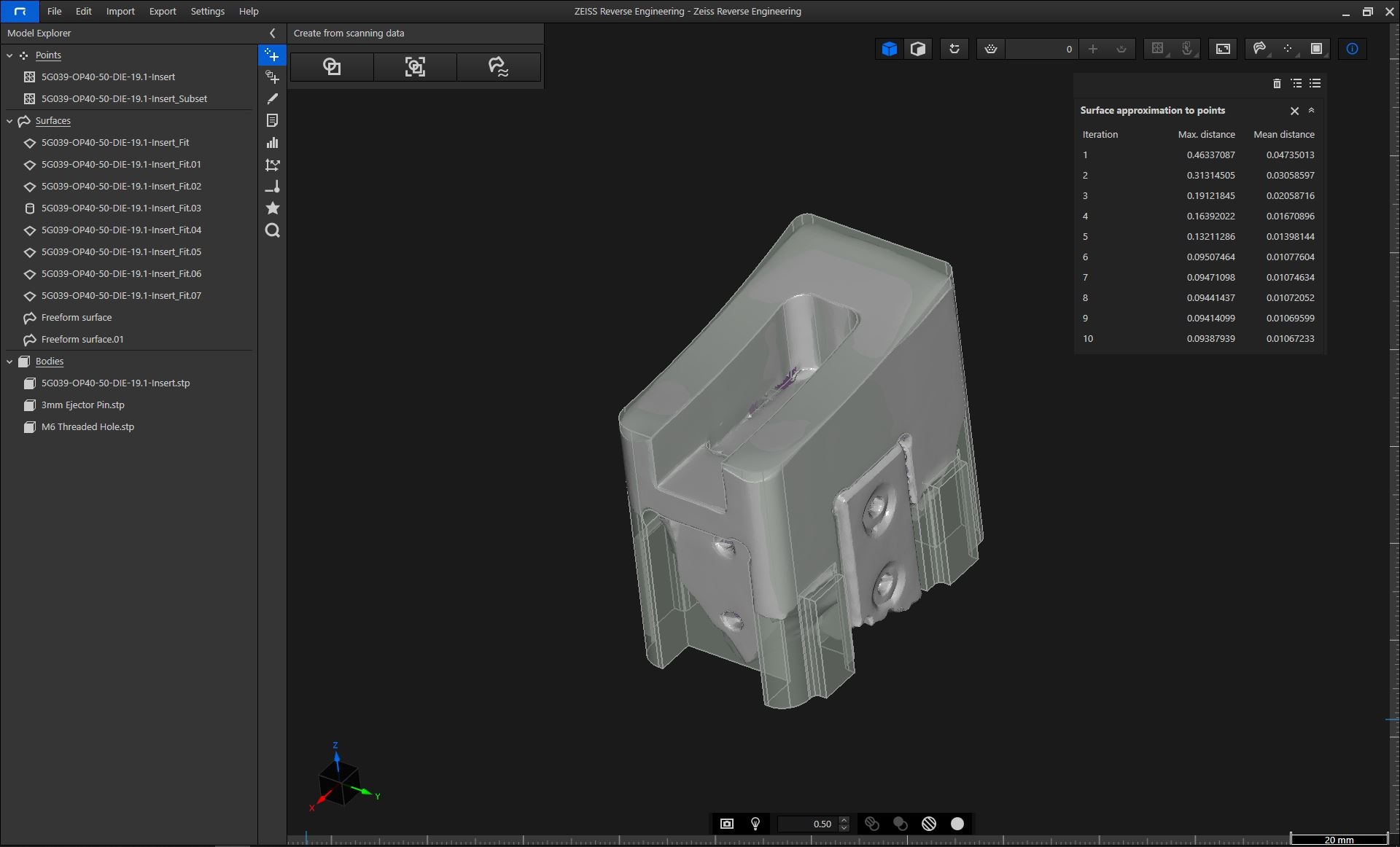

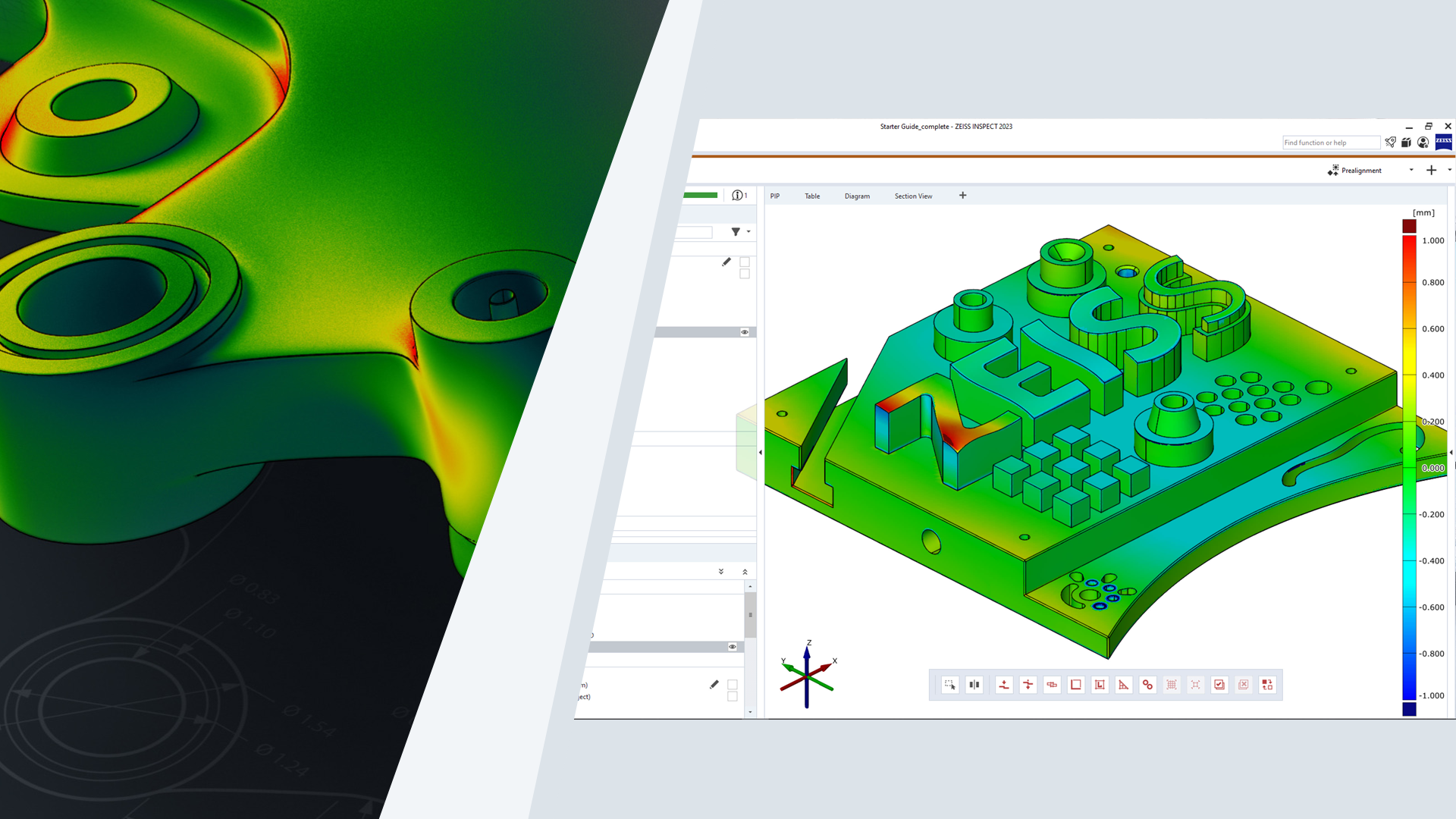

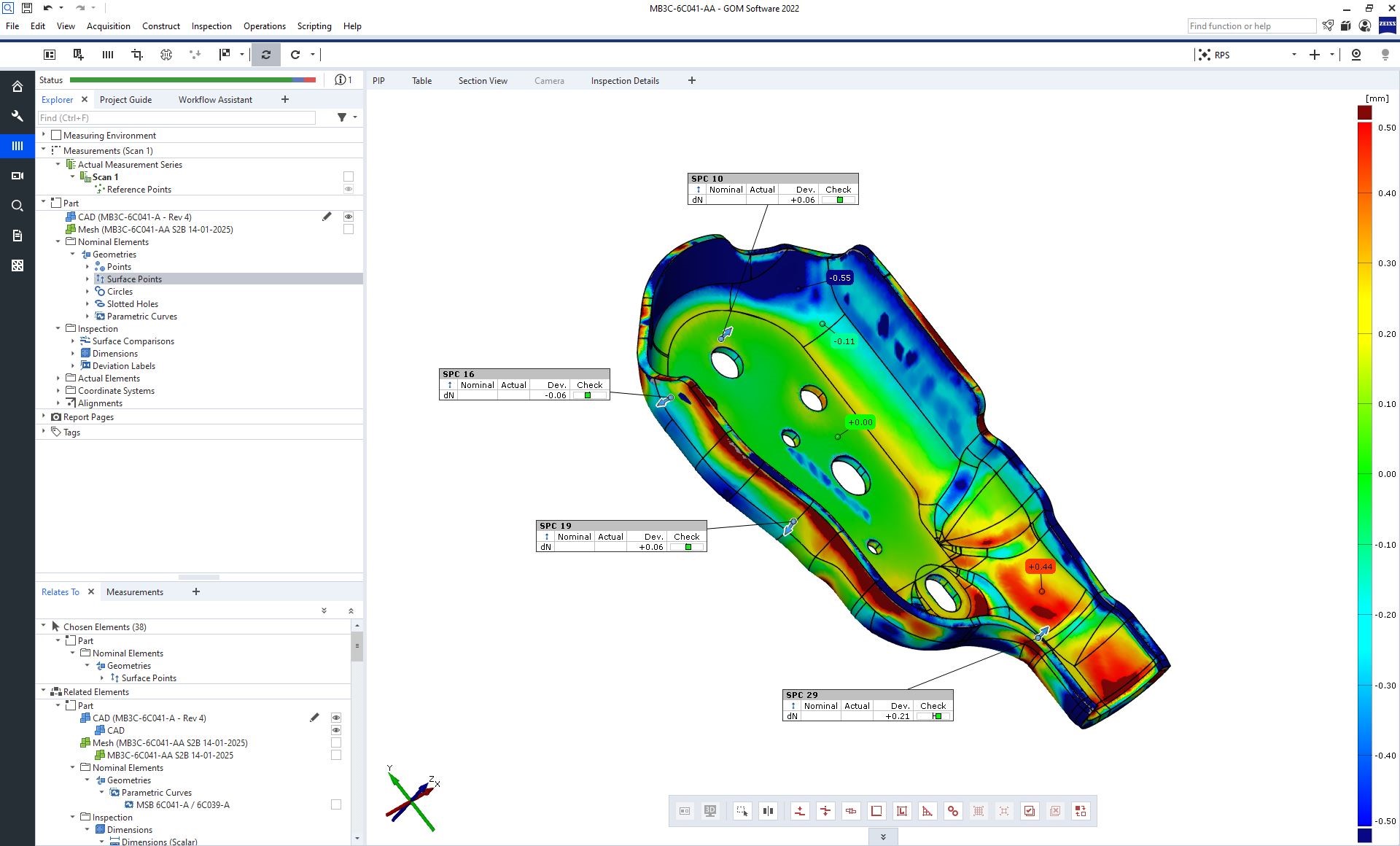

– ATOS 5 GOM Blue Light Scanning Systems, offering mobile, high-accuracy inspection and reverse engineering capabilities.

– Romer Absolute Arm, ideal for measuring jigs and fixtures installed on the production floor.

Continuous Monitoring and Evaluation

– SPC (Statistical Process Control) analysis to monitor and maintain process stability (Measurlink 9 Reak-Time SPC Software)

– Lab Crosscut Checks for assessing MIG weld integrity.

– Lab Induction Hardening Evaluations for heat-treated components.

– Inline Component and Assembly Checking Fixtures to ensure consistent part quality.

– Ultrasonic Spot Weld Evaluation for verifying the structural integrity of spot welds.

By combining cutting-edge technology with the expertise of our skilled quality control team, we ensure precision, efficiency, and compliance with the stringent demands of the automotive industry. Our commitment to innovation and excellence drives continuous improvement across all quality assurance processes.

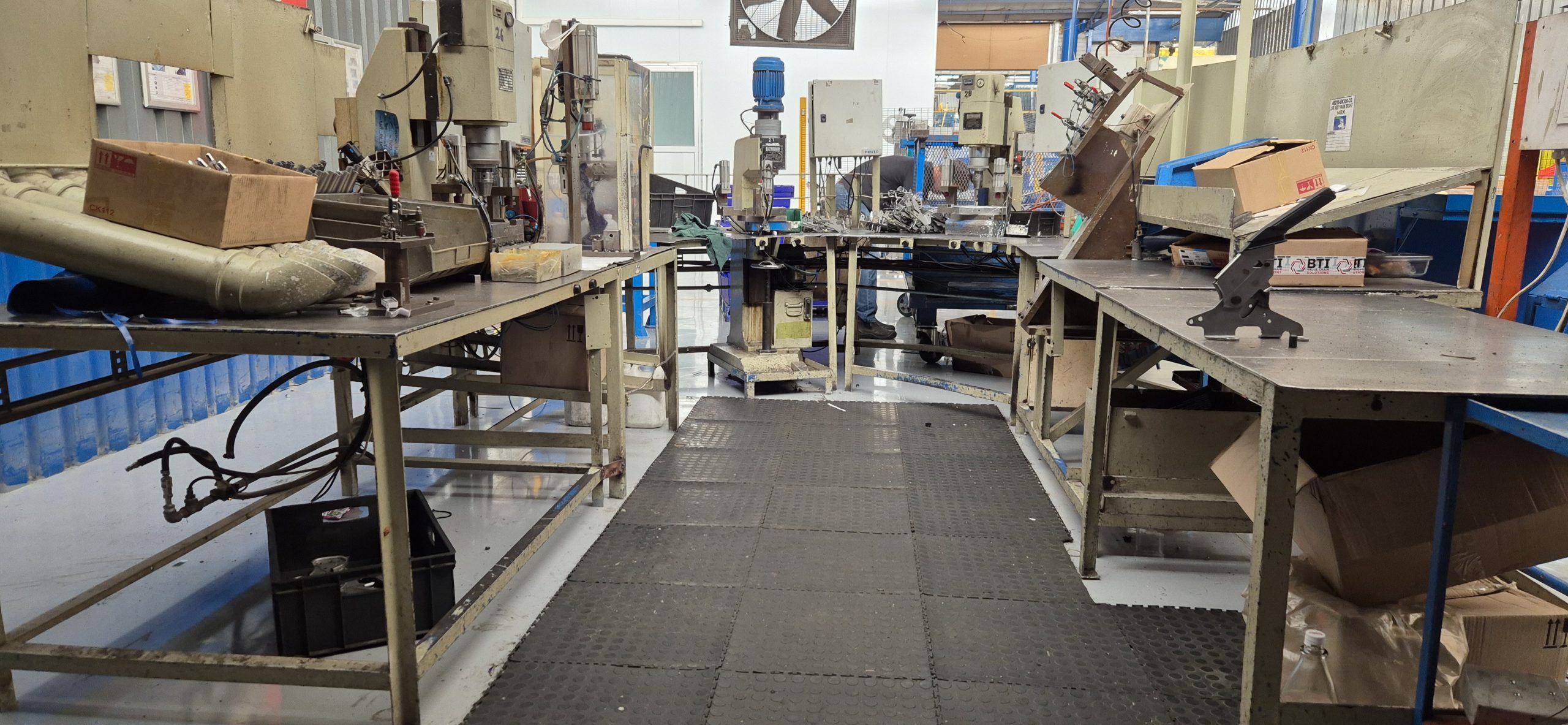

4.Tool Manufacturing & Machine Shop

Silverton Engineering’s in-house Tool Manufacturing and Machine Shop plays a critical role in supporting our production and engineering operations. Staffed by highly qualified toolmakers and machinists, the team specializes in the manufacture and repair of press dies—including progression dies and manual transfer dies—crafted from either fabricated materials or cast iron, depending on project requirements. Precision and reliability are at the core of our toolroom capabilities.

Key capabilities include:

CNC Machining Section:

– Victor 70 (800 x 460 mm)

– Victor 102 (1100 x 590 mm)

– AWEA (2100 x 1500 mm)

– 2x JM-168 Plus (1220 x 650 mm)

– JMC-3023 (3000 x 2000 mm)

Wire-Cutting Equipment:

– Fanuc Robocut C600iB

– Excetek V50

Additional Equipment:

– 2 radial drills for hole pitching

– 3 surface grinders for die sharpening and accurate punch sizing

– 3 manual milling machines for blocking and pitching

– 2 manual lathes

– Small induction oven for steel hardening

Software and Alignment Tools:

– Mastercam* software for CNC programming

– Spotting presses for precision punch alignment

Our shop combines high-end technology with hands-on expertise to ensure tooling is manufactured and maintained to exacting standards, meeting the rigorous demands of the automotive industry.

5. ENGINEERING DEPARTMENT

Our engineering department is the cornerstone of every implementation and project at Silverton Engineering. Comprised of qualified mechanical and industrial engineers, the team plays a vital role in ensuring the successful delivery of projects by collaborating with multiple departments, including maintenance, quality, logistics, and manufacturing. Their focus on continuous improvement and new project launches is complemented by a strong emphasis on quality, safety, and ergonomics.

Key attributes of the engineering department include:

Qualified Engineers: Skilled mechanical and industrial engineers driving project success.

Cross-Department Collaboration: Works closely with maintenance, quality, logistics, and production.

Continuous Improvement: Dedicated to enhancing processes and launching new projects.

Quality & Safety Focus: Prioritizing safety, ergonomics, and top-quality standards.

Software Tools:

AutoCAD for floor layouts and process improvements.

Dassault Systèmes Catia V5 for tool and die design.

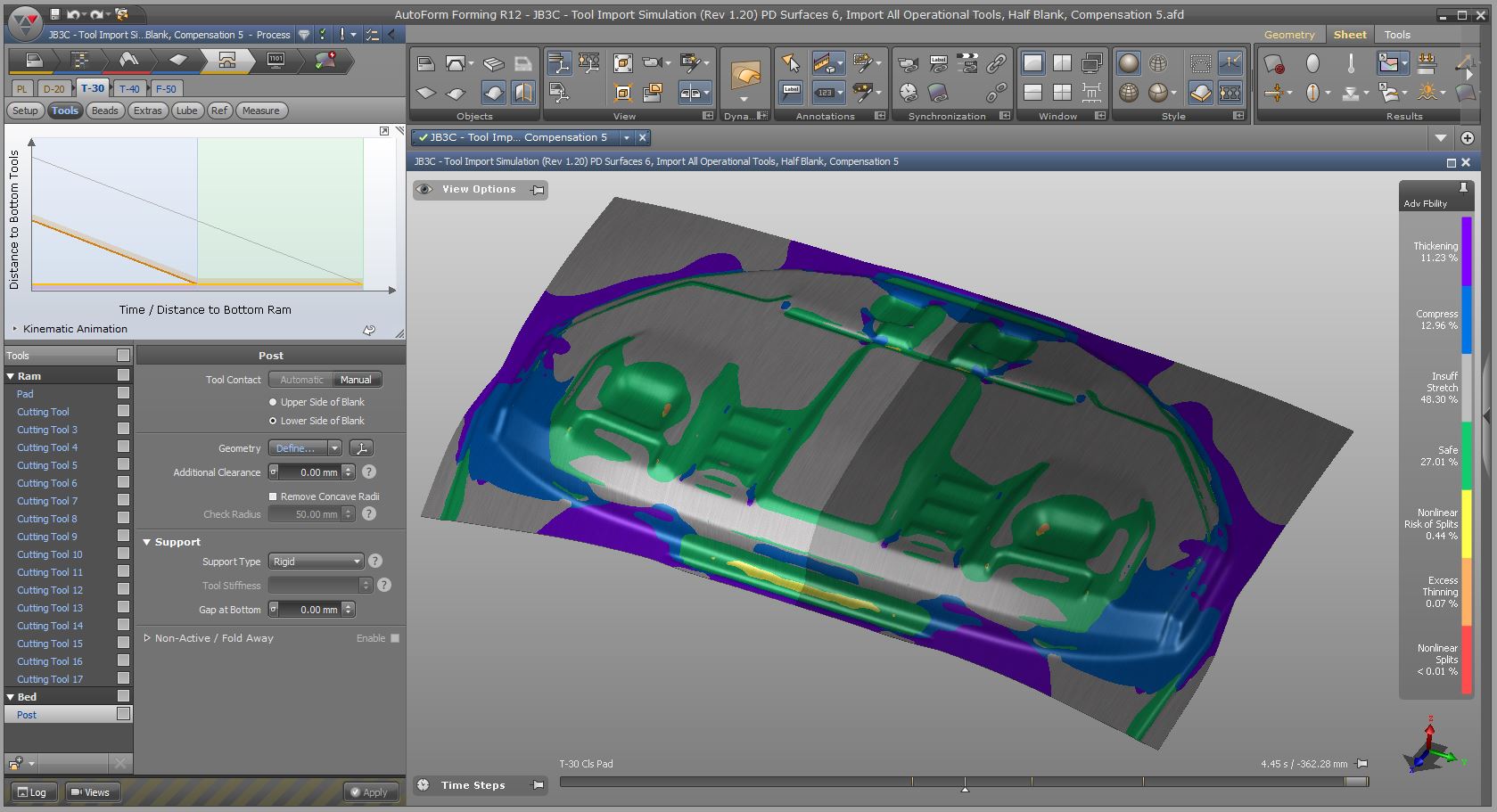

AutoForm for tool and die process design and feasibility.

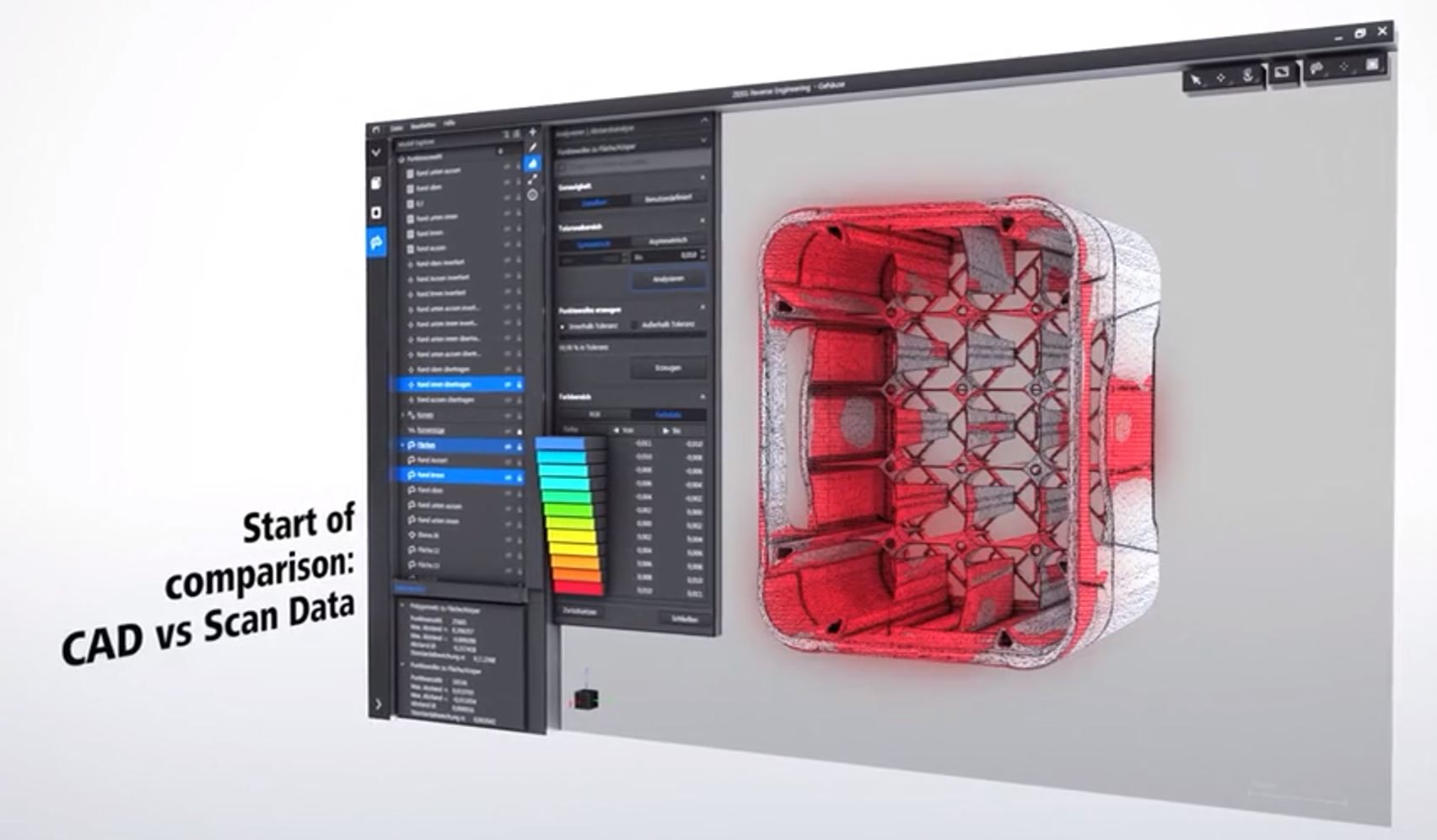

Zeiss Quality Suite combined with GOM Scanner for reverse engineering and quality assurance.

Best Practices: Applying cutting-edge technologies and methods tailored to specific project needs.

The engineering department at Silverton Engineering is committed to leveraging advanced tools and methodologies to achieve the highest level of design excellence and operational efficiency.